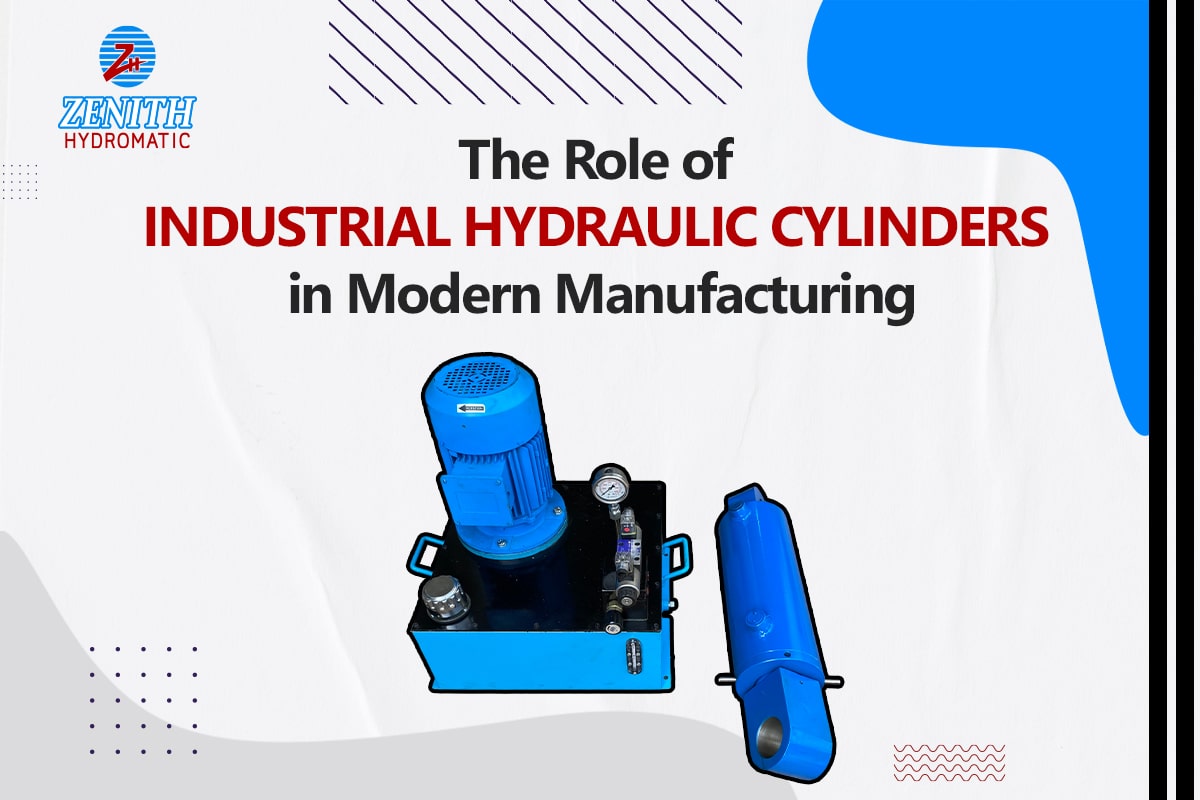

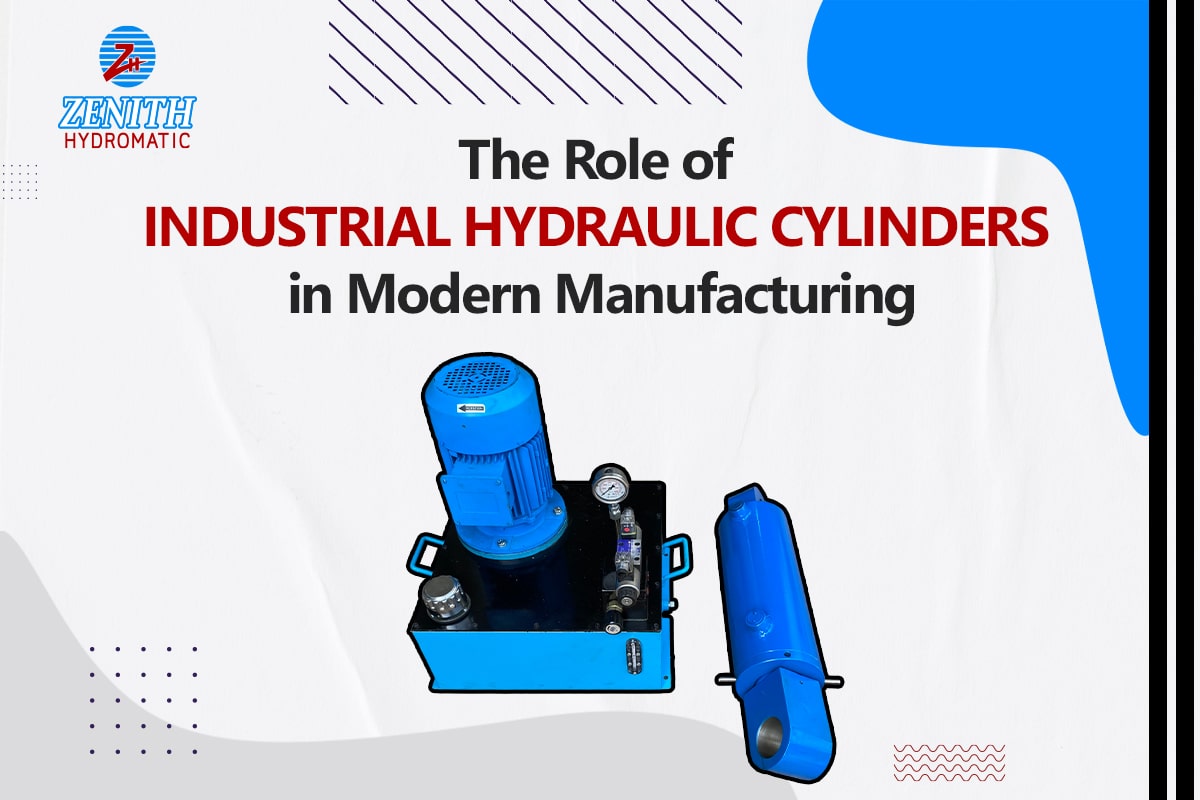

What are Industrial Hydraulic Cylinders?

Industrial hydraulic cylinders are mechanical actuators that employ pressurized hydraulic fluid to generate linear motion and force. They are made up of a cylinder barrel, a piston, and a piston rod. The hydraulic fluid is pushed into the cylinder, causing pressure to move the piston, which then moves the rod. This device turns fluid power into mechanical power, which allows heavy machinery and equipment to operate.

Types of Hydraulic Cylinders

- Single-Acting Cylinders: These cylinders produce force solely in one direction. The piston returns to its original position due to gravity or an external force.

- Double-Acting Cylinders: Double-acting cylinders can exert force in both directions because hydraulic fluid is alternately poured into either side of the piston.

- Telescopic Cylinders: These cylinders have multiple stages and provide extended reach while remaining compact.

Applications of Hydraulic Cylinders in Manufacturing

-

Automotive Industry

Hydraulic cylinders are essential components in the vehicle production process. They are used on assembly lines for stamping, molding, and lifting heavy components. They ensure precision and efficiency in procedures requiring high force and controlled motion.

-

Aerospace Industry

Hydraulic cylinders are used to manufacture and test aerospace equipment. They provide the necessary force for machining and shaping aerospace components, assuring the high precision and dependability required in the industry.

-

Construction and Mining

Excavators, bulldozers, and cranes all require hydraulic cylinders to function properly. They allow for heavy lifting, digging, and material handling, making them vital in various industries.

-

Heavy Machinery and Equipment

Hydraulic cylinders are employed in a variety of heavy machinery and equipment in the manufacturing industry. They make operations easier in presses, injection molding machines, and material handling systems, resulting in greater productivity and efficiency.

Advantages of Using Hydraulic Cylinders

-

High Force Generation

One of the key benefits of hydraulic cylinders is their capacity to generate significant force. This qualifies them for tasks needing great power, such as lifting huge loads and running large machines.

-

Precision and Control

Hydraulic cylinders provide certain control over motion and force, which is essential in manufacturing processes that demand accuracy. The ability to fine-tune the piston’s speed and position improves the quality of the finished product.

-

Durability and Reliability

Hydraulic cylinders are designed to resist severe environments and heavy use. Their rugged design and dependable performance make them a popular choice in industries where downtime is costly.

-

Versatility in Applications

Hydraulic cylinders are versatile and can be used in a variety of applications across industries. Their versatility to various jobs and settings makes them an indispensable component of modern manufacturing.

Technology Behind Hydraulic Cylinders

-

Materials and Construction

Hydraulic cylinders are often composed of high-strength materials like steel and aluminum. The materials used ensure durability and resistance to wear and tear, hence increasing the cylinders’ lifespan.

-

Advanced Sealing Technology

Seals are essential components of hydraulic cylinders, preventing fluid loss and maintaining pressure. Advances in sealing technology have resulted in the development of seals that can tolerate high temperatures and pressures, improving the performance of hydraulic cylinders.

-

Innovations in Design and Manufacturing

Continuous improvements in design and production have resulted in more efficient and dependable hydraulic cylinders. Computer-aided design (CAD) and modern production techniques, such as CNC machining, have enhanced hydraulic cylinder precision and quality.

Selecting the Right Hydraulic Cylinder Manufacturer

-

Key Factors to Consider

When choosing a hydraulic cylinder manufacturer, consider experience, reputation, and the capacity to supply customized solutions. It is critical to select a company that uses high-quality materials and follows strict quality control guidelines.

-

Importance of Quality and Customization

Quality and customization are essential for ensuring that hydraulic cylinders satisfy the unique requirements of your application. A reputable manufacturer will provide specialized solutions to improve the performance and efficiency of your machines.

-

Future Trends in Hydraulic Cylinder Manufacturing

The future of hydraulic cylinder manufacture is dependent on developments in materials, design, and technology. Smart sensors and IoT integration are projected to improve hydraulic system functionality and monitoring, resulting in higher efficiency and lower downtime.

Conclusion

Industrial hydraulic cylinders are essential in modern manufacturing because they provide the force and precision required for various applications. Their high force generation, precision, durability, and adaptability make them valuable components in a variety of sectors.

By selecting the correct hydraulic cylinder manufacturer, you can assure the dependability and effectiveness of your machinery, thereby contributing to the success of your manufacturing business. As technology advances, hydraulic cylinders will play an even more important role in production, driving industry innovation and productivity.

For more detailed information, you can visit their website Zenith Hydromatic or contact them directly at +91 9426326091 or sales@zenithhydromatic.com. Choosing Zenith Hydromatic for your hydraulic needs ensures you receive top-quality products and exceptional service.